With the aim in providing service to domestic industries, RAYA TEJARAT ESPADANA Engineering Co. was established in the industrial city of Esfahan, Iran, in 2007. Members of this company have been gathered to be the knowledgeable partners for the owners of industries and trustful leaders for the company’s customers, by specialized researches in the field of industrial diagnosis, transferring new technologies and transferring technical knowledge, manufacturing and startupproduction lines, industrial automation, procuring raw materials and components. Thus, a combination experienced forces and executive managers, together with experienced experts and competent domestic and foreign consultants, among the human forces of this company, are working in an environment rich in loyalty and veracity, in order to have long steps in the growth and eminence of the country’s industrial cycle by identifying risky industrial bottlenecks, eliminating the bottlenecks, and removing considerable problems in the field of industry.

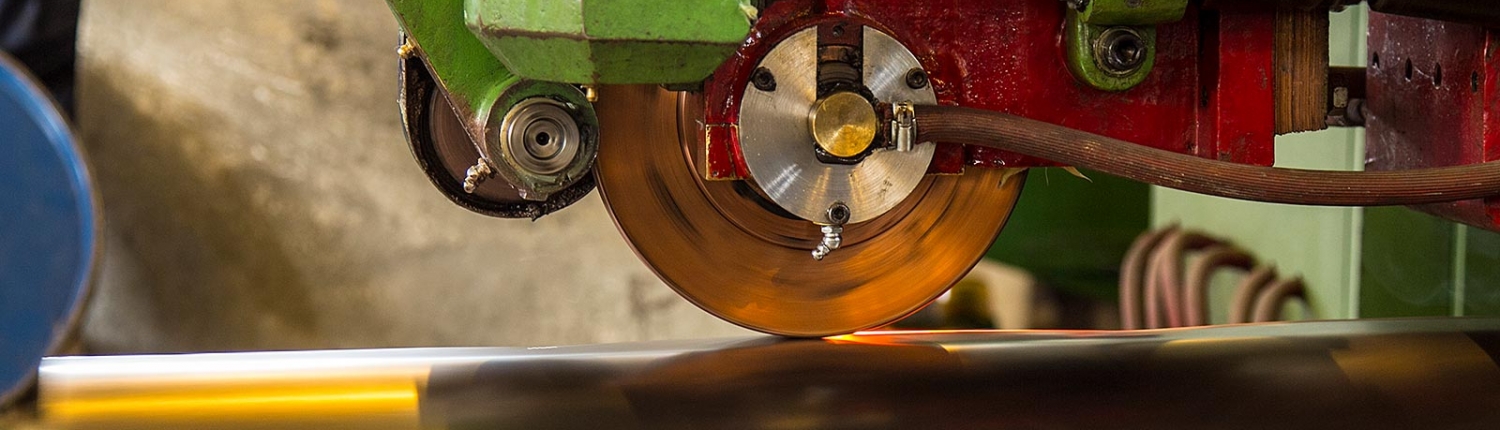

PROCUREMENT AND INSTALLATION OF INDUSTRIAL MACHINERY

The process of selecting required machinery and technical advices, purchasing, installation and startup of equipment, and selection of appropriate technologies with regards to consumable resources, installation and startup of equipment as well as supplying spare parts are done through primary studies and estimating related machinery requirements by the purchasing engineering team of the company.